- ---We are a group of companies specializing in revolutionizing tire recycling machines. Our main recycling field is automatic waste tire recycling plants.

- ---Tire recycling machines have low energy consumption and wide use, to reduce the cost of waste tire storage and tire delivery. The aim is to get customers from tire recycling to creating innovative value and recycled rubber products.

- ---A complete tire recycling production line, also known as a rubber granule recycling plant or rubber powder recycling plant, uses advanced revolutionizing tire recycling technology to use waste tires recycling rubber granules or powder.

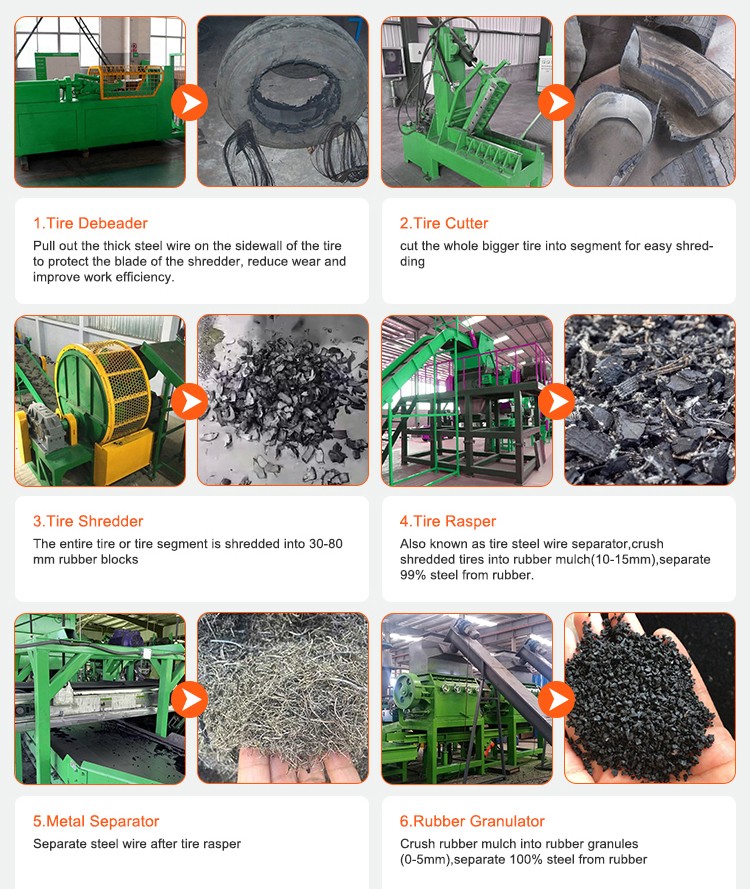

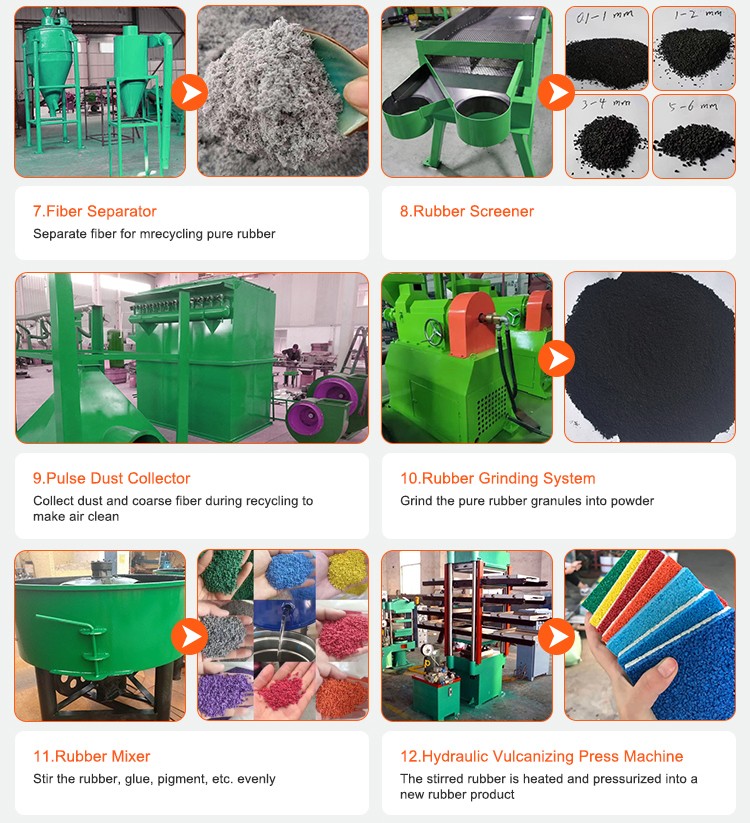

- ---The tire recycling process involves a series of machines that shred the tire into tire blocks as TDF, raspe the tire blocks into rubber mulch and separate steel wire, granule the mulch into rubber particles and separate the fiber, mill the pure rubber into rubber powder. The rubber can be made into alternative uses for recycled rubber to create new values, like Playground surfaces, Road surfaces and infrastructure, Vehicle mats and interiors, Gardening products and equipment and so on.

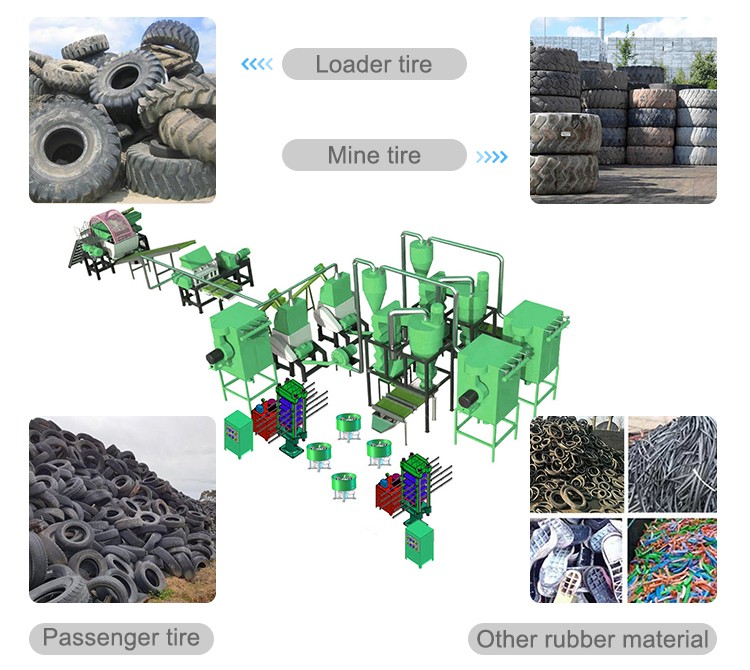

Perfect for Tire Type:

Waste tire recycling plants can achieve rubber chips, rubber mulch, rubber particles, and rubber powder. There are many products and uses for recycled rubber, and some of them are more commonplace than you might think.

- ---Flooring – Contaminant-free rubber granules – you will find the rubber granules made by tire recycling plants to be only of the highest grade. The same that is used in football, soccer, and other athletic fields sporting artificial turf, protecting you and the ground you just dropped that weight on is probably some type of recycled rubber mat.

- ---Bumpers – Contaminant-free rubber powder – you will find the highest grade rubber powder made by tire recycling plants. these come in all shapes sizes and uses– from shipping docks and boat docks to wheel chocks, door stops, and wedges.

- ---Animal mats – nothing says waterproof or urineproof like rubber. You will find these in many homes and even in equestrian parks and facilities.

- ---Asphalt additive – once again another application where tires meet the recycled tires.

Product Details:

Recycling Rubber Product Display:

We are building sustainable future with Tire Recycling Plant.Final products are for infill artificial grass, poured in place, bark for mulch - colored rubber granules,rubber athletic tracks,rubber tennis courts,rubber bowls court,rubber paratrooper,rubber building soundproofing,rubber playground,rubber pavement, traffic warning products, sports products,new tires and so on.

How tyre recycle plant works?

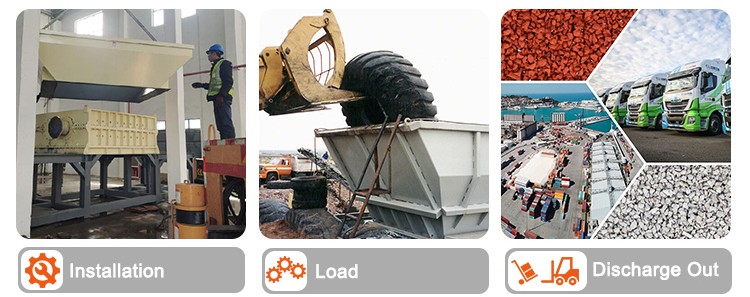

---Installation: The floor space of the tire recycling production line covers a smaller area and requires a 3-phase connection. Because of the installation of the whole plant, or retaining power and shredding parts, almost no additional installation, is directly connected to the power supply. Our technician will guide the installation process.

---Load: The open top allows continuous loading of waste. Fully automatic control of the PLC distributes power output according to feeding conditions with perfect machine design, and uniform feed, the tire recycling production line will automatically continue to run and cycle.

---Discharge out: The tire recycling production line is a full pass rate machine with a screen, so you can get any final sizes. The whole recycling plant will discharge the material continuously according to the feeding condition.

- ---Environmental benefits: By recycling used tires, waste tire recycling plants help reduce the amount of rubber waste that ends up in landfills or illegally dumped in the environment. This helps prevent pollution and reduces the impact on natural ecosystems.

- ---Resource conservation: Recycling used tires helps conserve valuable resources such as rubber, steel, and other materials used in tire production. This reduces the need for new raw materials and helps conserve energy.

- ---Economic opportunities: tyre recycling plants create job opportunities and contribute to the economy. They also provide a source of sustainable raw materials for various industries, such as the automotive, construction, and manufacturing sectors.

- ---Energy recovery: In addition to recycling rubber and other materials, waste tyre recycling plants can also recover energy from used tires through processes such as pyrolysis or gasification. This helps reduce the demand for fossil fuels and contributes to the development of renewable energy sources.

Optional accessories:

Features & Benefits:

Tire recycling plant cost:

|

Model |

0.3TPH-SA |

0.5TPH-SA |

0.8TPH-SA |

1TPH-FA |

1.5TPH-FA |

2TPH-FA |

|

|

Adopts Upper And Lower Shells, Steel Plate Bolted Structure |

|||||

|

Plant Area |

80 m2 |

100 m2 |

115 m2 |

180 m2 |

220 m2 |

280 m2 |

|

Working Capacity |

About 0.3 T/H |

About 0.5 T/H |

About 0.8 T/H |

About 1 T/H |

About 1.5 T/H |

About 2 T/H |

|

Working Speed |

3-4 min from feeding Material to Rubber Granules |

|||||

|

Installation Design |

Depending on the size of the site, it can be installed in I-type or L-type or Z-type installation |

|||||

|

Weight |

16000 Kg |

18500 Kg |

22000 Kg |

33500 Kg |

40000 Kg |

52000 Kg |

|

No-Load Noise |

In 1meter ≦75 db.(A) |

|||||

If you have any suggestions or opinions about our products,please leave a message,and we will immediately answer your questions. Thanks for your support.